Fanuc Robotics Simulation Software Download

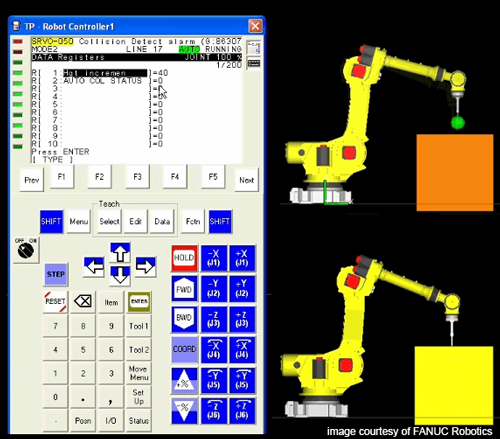

The following video featuring FANUC Robotics' ROBOGUIDE Simulation Software, comes courtesy of FANUC Robotics Authorized Integrator Automated Cells & Equipment. FANUC Robotics' ROBOGUIDE family of simulation software packages provide the ability to create, program and simulate a robotic workcell in 3-D, without the need or expense of physical prototypes.

Intelligent 3-D robot simulation FANUC ROBOGUIDE is a robot simulator that simulates both the robot’s motion and application commands, significantly reducing the time it takes to create new motion setups. To ensure minimal impact on production, cells can be designed, tested and modified entirely offline. To save 3-D modelling time, part models can be imported from a PC as CAD data. The robot simulation software’s extensive library also allows users to select and modify parts and dimensions as required. Designed to be intuitive and extremely easy to use, ROBOGUIDE requires very little, if any, training.

It is also available with dedicated tools for specific applications. Learn more about the newest features for your intelligent 3D simulation software.

Rochester Hills, Mich. – introduced its new robot simulation software, SimPRO, and PalletPRO, a palletizing process solution software, at Worldwide Food October 18 at the McCormick Center in Chicago. These products provide sales, proposal and application engineers the tools needed to simulate robotic workcells without the time and costs associated with a prototype setup.

Driver dlya veb kameri samsung vg stc 2000 download. Fanuc Robotics’ M-410i robot will be featured in a palletizing application, which will showcase SimPRO, FANUC Robotics’ new offline robot simulation software with the Virtual Robot Controller. SimPRO allows users to simulate a robotic process in 3-D space. Tugilgan kun hakida sherlar foto. SimPRO provides the most accurate cycle time information for Fanuc robots compared to any other simulation package available in the industry. ‘SimPRO will be a great time and money-saving tool for sales, proposal, and application engineers who develop robotic systems,’ said Ranganath Misra, engineering manager for material handling products and applications, Fanuc Robotics. ‘To be competitive, companies must utilize tools that quickly provide reliable, accurate information about a robotic application without the physical need and expense of a prototype setup. SimPRO provides these tools.’ With SimPRO sales, proposal and application engineers can import unique CAD models of parts, create a workcell including machines, part transfer devices and obstacles and teach robot paths to simulate the operation and performance of a robotic application.

Reach verification, collision detection, accurate cycle time estimates and other visual system operations are simulated in SimPRO’s unique and graphical virtual environment. SimPRO provides the ideal simulation for general-purpose material handling applications including pick and place, machine load/unload, packaging, material removal, assembly and simple palletizing. For the simulation of more advanced palletizing applications, FANUC Robotics also offers a SimPRO plug-in option – PalletPRO, which will also be showcased in FANUC Robotics’ booth. PalletPRO provides the additional tools needed to set up a palletizing cell, verify system throughput, verify reach, and detect collisions. Users can create pallet workcells and define palletizing parameters by creating unit loads with PalletTool PC. Standard items used in palletizing workcells such as slip sheets, conveyors, dispensers, etc. Are included in the package.

The advantages of PalletPRO include fast cell setup and accurate cycle time because simulation is running with Fanuc Robotics’ PalletTool software. The offline simulation package also helps reduce the cost, effort and time needed during workcell integration. ‘PalletPRO not only allows accurate estimate of cycle times, but it will also increase the productivity of the integrators and end users by allowing them to easily build, test and debug their palletizing systems off-line,’ said Nishant Jhaveri, engineer, Fanuc Robotics. ‘This will reduce time, cost and effort during workcell integration.’.